Painting and Engraving

The market asked and we added two new work centers to deliver custom painting and engraving needs for our custom manufacturing customers.

Whether you need primer grey, safety yellow, custom branded pantones, stenciling, or just part numbers engraved, we have the equipment and skills for your final project step.

Feel free to schedule a tour to view our capabilities and meet the skilled team that will be working on your projects.

Scroll down for more information or submit you Request for Quote to get started.

If it fits, it can be painted, stenciled, and engraved.

Latest project include:

- Painting safety yellow and stenciling of vinyl serial numbers on aircraft repair stands.

- Custom matched pantones sprayed on parts to match customer branding standards.

- Custom thickness requirements applied per print and customer Manufacturing Operations Procedures (MOP).

- Masking and primer grey applied for customer to apply final surface paint in the field.

- Refinishing of repaired equipment to match original OEM specifications.

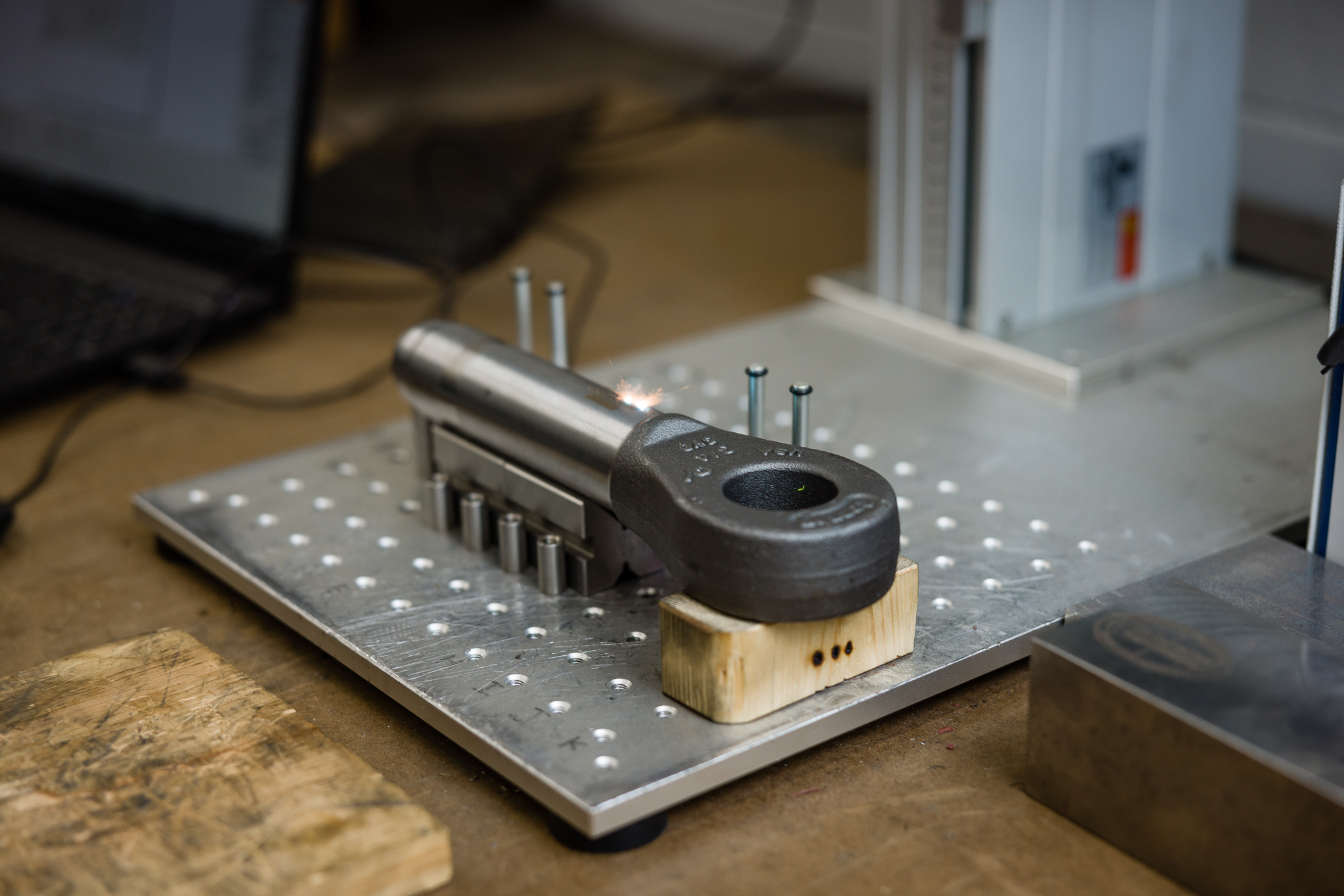

Laser engraving and parts marking.

Latest projects include:

- Parts engraved to customer specifications to include PO, customer #, part #, and serialization requirements.

- Custom logos engraved for end user branding.

- CNC machining for identification specs for larger parts.

- Engraving on curved surfaced and exterior of part radiuses.

Custom color matching to any surface.

Latest projects include:

- Providing color match and surface finish requirements for contract manufacturing customer.

- Masking, priming, weather proof painting of assembly fixtures for solar panel installation.

- Refinishing of repaired and refurbished OEM equipment for industrial equipment manufacturer.

- Texture applications for non-slip surfaces on platforms and scaffolding.