You need 1200 units per year but only have the budget to purchase to your customer orders. We handle the supply chain for materials, keep an average amount of finished goods on the shelf, and deliver the needed quantity just in time. We can custom design a modified stocking plan that fits your demand and lead times.

Overview

Summary

We have countless phone calls about why our lead times are so far out when the customer needs the parts in two weeks. After the fourth or fifth conversation with the same individuals, it is clear that you are reacting to incoming orders of your own, and without a clear forecast from your customer, you can’t commit the finances and the carrying costs of having six months supply on the shelf.

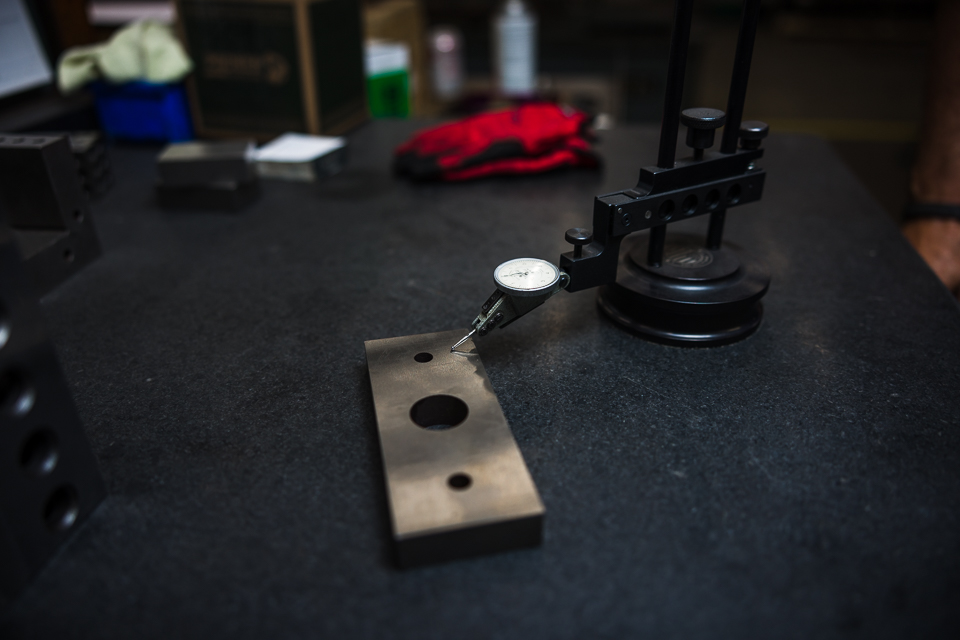

Let us help you like we help over a dozen manufacturers receive the quantity of custom parts they need within five business days by custom designing a modified stocking program where we maintain a quantity of raw material and finished goods based on your EAU.

We take the relationship with the raw material and service providers which allows your purchasing team to focus on more important jobs. This allows us to complete your parts in shoulder times which lowers the labor costs and fills machine time in the off shifts for us which drives unit cost savings since you do not use peek times. Using your estimated forecast for EAU, we keep an agreed amount of finished goods on our shelfs which allows you to order just in time to fill your own orders faster and consistently.

The business case:

- Allows a better use of capital since you are not ordering a year worth of material.

- Lowers your inventory and carrying costs of slower moving parts.

- Accelerates your lead time to your customer.

- Shortens the sales cycle and gives predictable costs of goods sold.

- Allows you to outsource slower moving legacy parts so you can focus internal resources on higher margin jobs.

- Allows you to order less quantities more frequently thus improving cash flow.

A second scenario is for you to order the material because you have greater purchasing power and national relationships with vendors and have us store the raw material and still keep an agreed amount of finished goods on the shelf. The cost to you is just for the labor used to produce your parts and again allows your internal resources to focus on higher rated business. This ultimately lowers your unit cost given your purchasing power and still uses labor efficiently from us and still shortens the sales cycle to your customers.

If you are tired of the fire drill every time you receive a repeat PO for legacy parts and want to shorten your lead times and control variable costs, contact us to start the conversation.

Problem

Journey/Process

Solution