All of the manufacturing world has experienced increasing timeline creep from expected time to delivery to actual delivery. This was, and still is, caused by the supply chain supernova that occurred early in the decade. So how do you improve lead times?

By addressing certain internal and external constraints, companies can win back on-time delivery ratings to the customer and give back costs, time, energy and misapplied labor to their ongoing goals of continuous improvement to increase performance.

However, let us first look at how we got to this topic.

A Long Long Time Ago…………

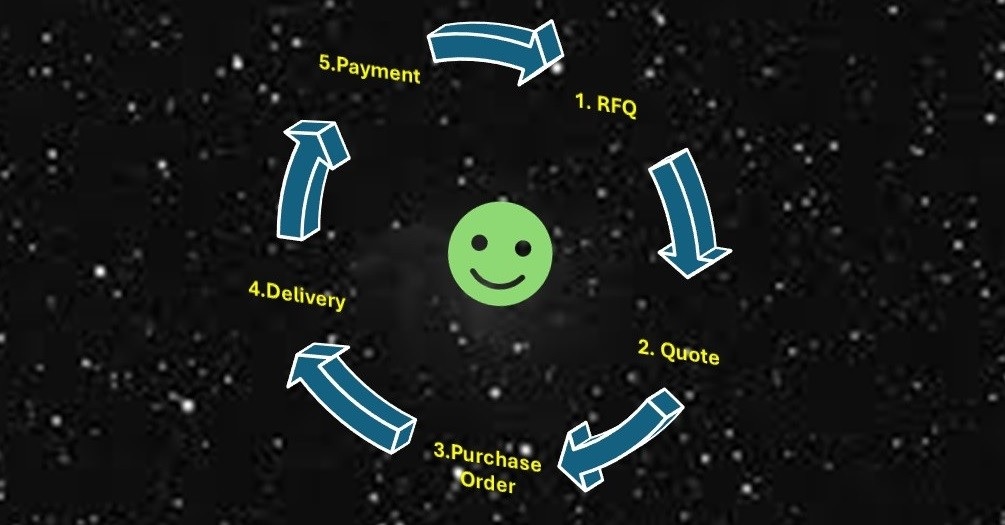

In the beginning, a beautiful process was created out of years of commerce that included seamlessness between the following orders of operation:

- Requesting a quote from a supplier

- Receiving a quote

- Sending a purchase order

- Receiving your order

- Paying your invoice

All was right in the universe for years as we operated our supply chains and provided quality and on-time orders to our customers.

It Is Never Coming Back!

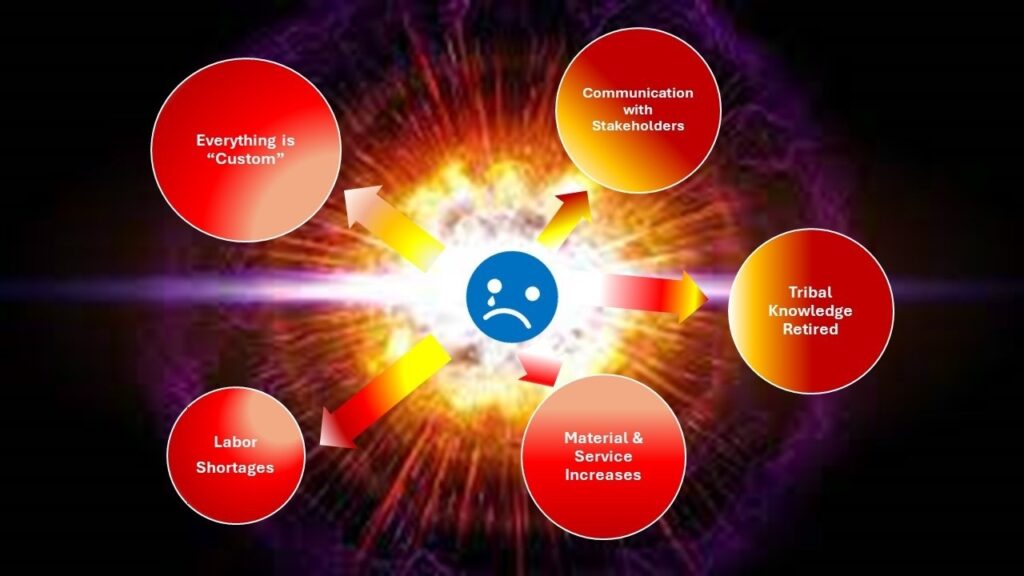

But then, in a matter of weeks, the harmonious universe that was a beautifully built and coordinated system of interdependent private businesses all aligned on quality and on-time deliveries went super nova thus vaporizing the great functioning parts into oblivion.

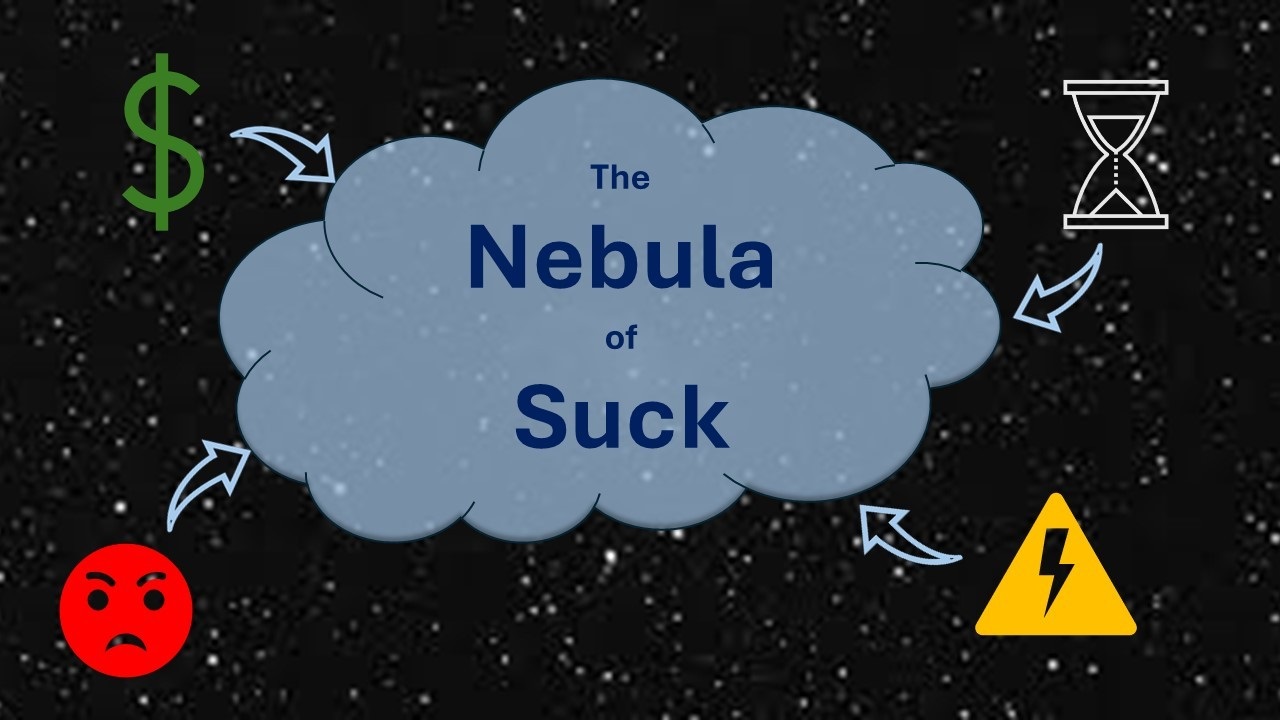

A few remnants of what was once a beautiful system of commerce are left but other parts changed form and became the “Nebula of Suck” that still exists today. These include:

- Off the shelf items that were once stocked and readily available now became “custom” with increased lead times and prices.

- Communication between stakeholders became blackholes of activity with remote working policies and decentralized accountability when answers are needed for clarification on bills of materials and print discrepancies.

- The experience and expertise in purchasing, engineering, production, and business management retired early and took with them the tribal knowledge that was never documented to pass on to others.

- Material and services costs exploded overnight creating budget nightmares and extended timelines for decisions.

- That diminishing pipeline of qualified and skilled labor that has been warned about for over forty years, finally happened.

Terms like “pivot” and “new normal” were added to the Webster Dictionary overnight and to this day, there are still purchasing managers stuck in stage one of grief and send PO’s with 2017 lead times which places them in stage two pretty quickly.

What are you doing and how do you improve lead times for your customers?

7 Short Term Solutions: Control What You Can Control

Agility and responsiveness will continue to separate the weak from the successful when it comes to customer satisfaction and as costs for materials and services have plateaued for now, lead times can set you apart.

I can argue that you can buy time if the following constraints are given energy before you even submit the RFQ to a vendor.

- Providing the latest prints, solid models, and bills of materials.

- Being available and respond timely to questions

- Collaborating with the stakeholders before you quote

- Not over promising and maintaining transparency

- Knowing your production schedule

- Communicating with your supply chain

- Having a back up plan

You can read further about each of these points on LinkedIn here.

7 Long Term Solutions: Make Plans for Everything Else

- Drafting and developing from different channels

- Looking at non-traditional scheduling

- Always be learning

- Partnering with the best suppliers

- Hiring for innate qualities

- Diversifying and vertically integrating

- Clearing the runway for great ideas

You can read further about each of these points on LinkedIn here.

Keep On Keeping On!

No matter what the world throws at us, the values and beliefs that made American Manufacturing great will persevere and continue to evolve to drive new efficiencies and produce more with less.

For 70 years, Allis Manufacturing Corp. in Milwaukee, WI has proudly provided large machining, welding, assembly, repair and rebuild, and now painting and engraving for over a dozen industries. We consider ourselves a learning and teaching organization that not only takes pride in our quality and on-time rating but is also dedicated to helping #Neurodiverse individuals find meaningful employment in manufacturing.